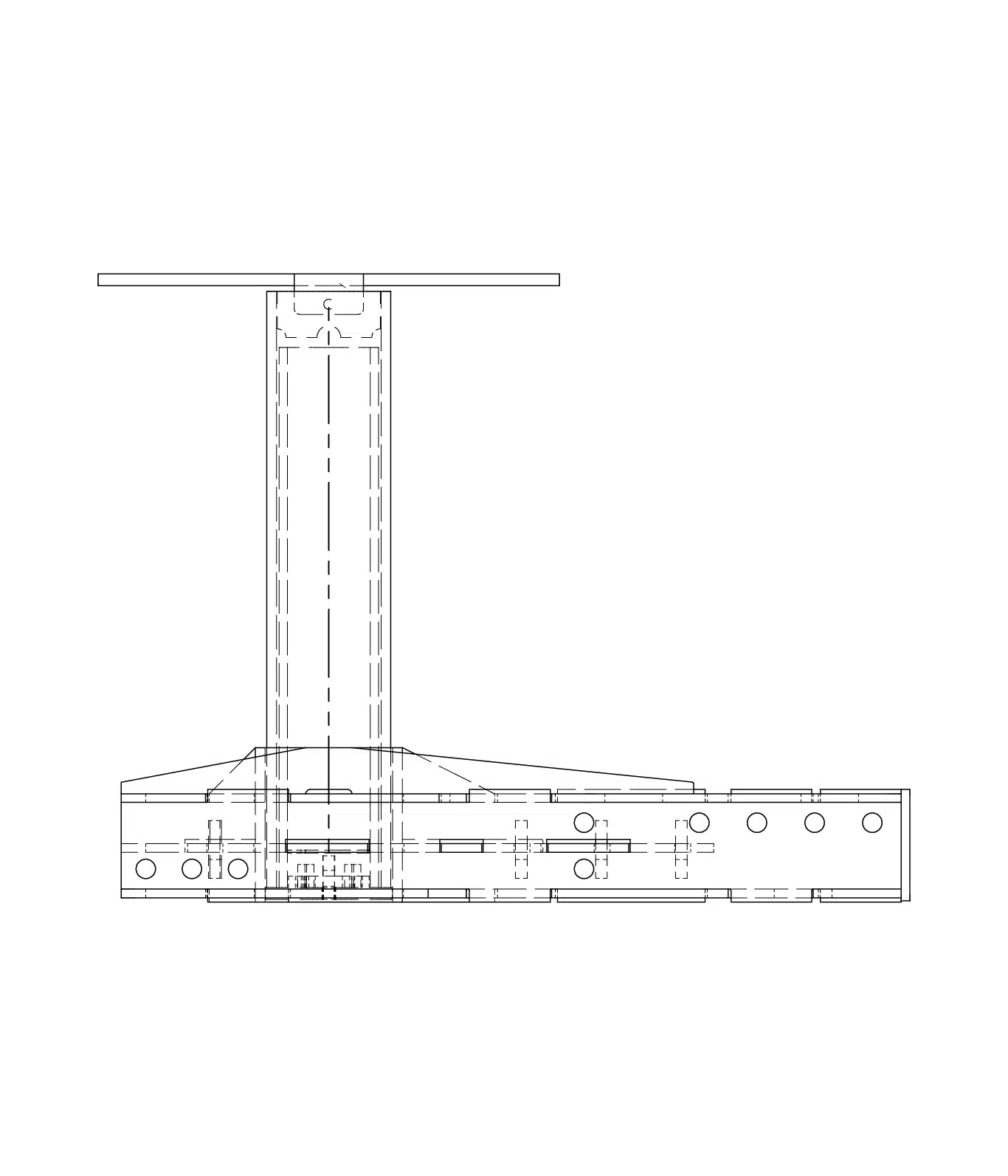

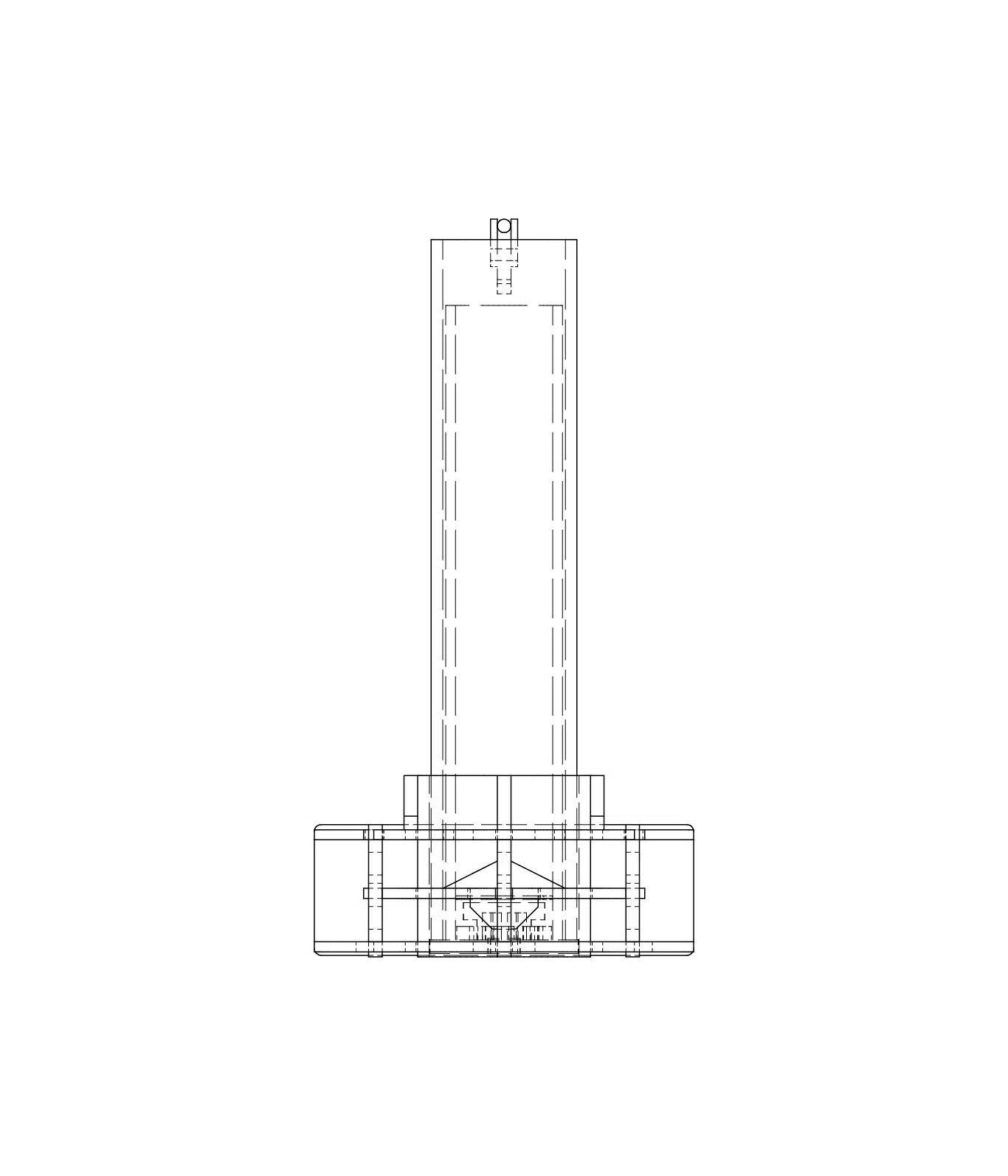

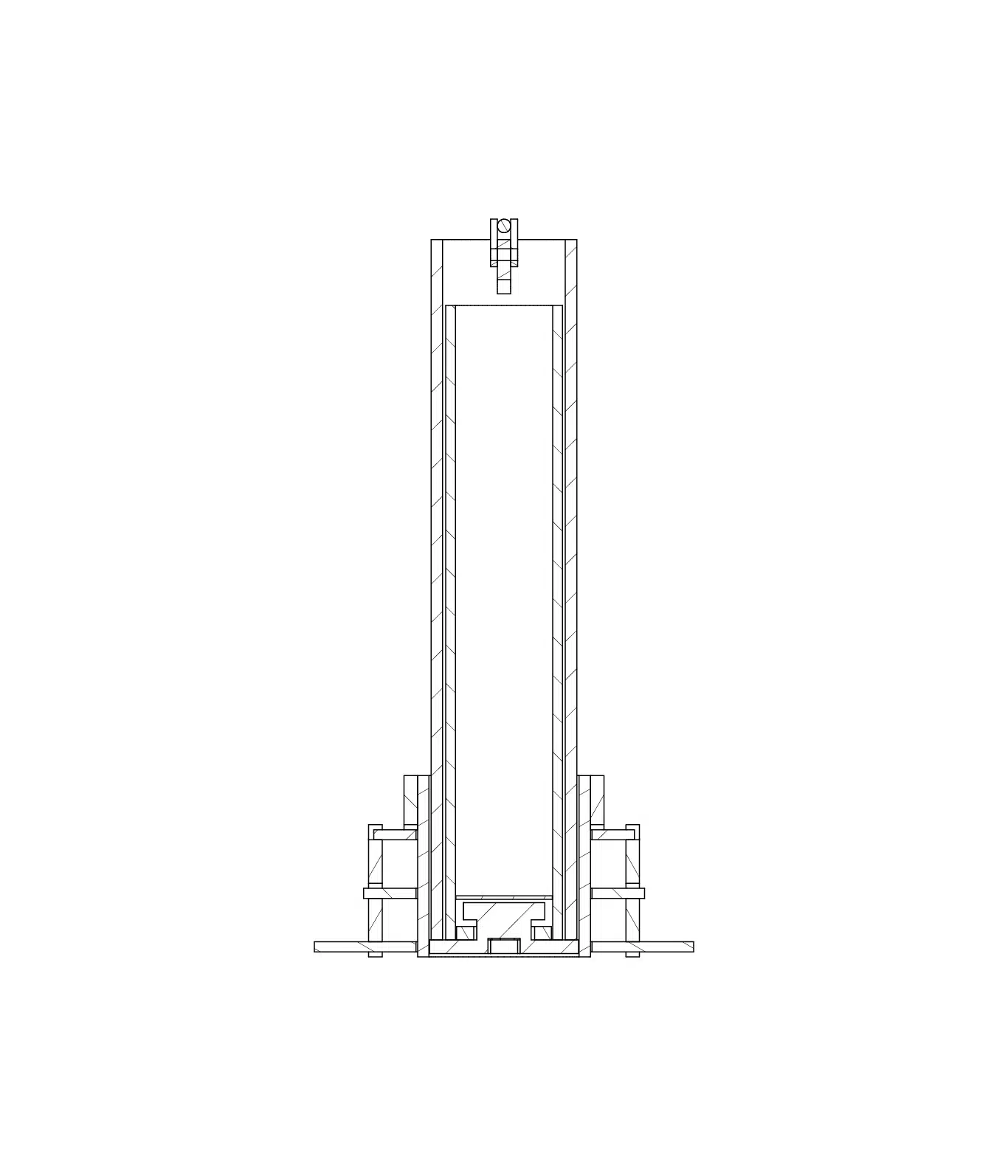

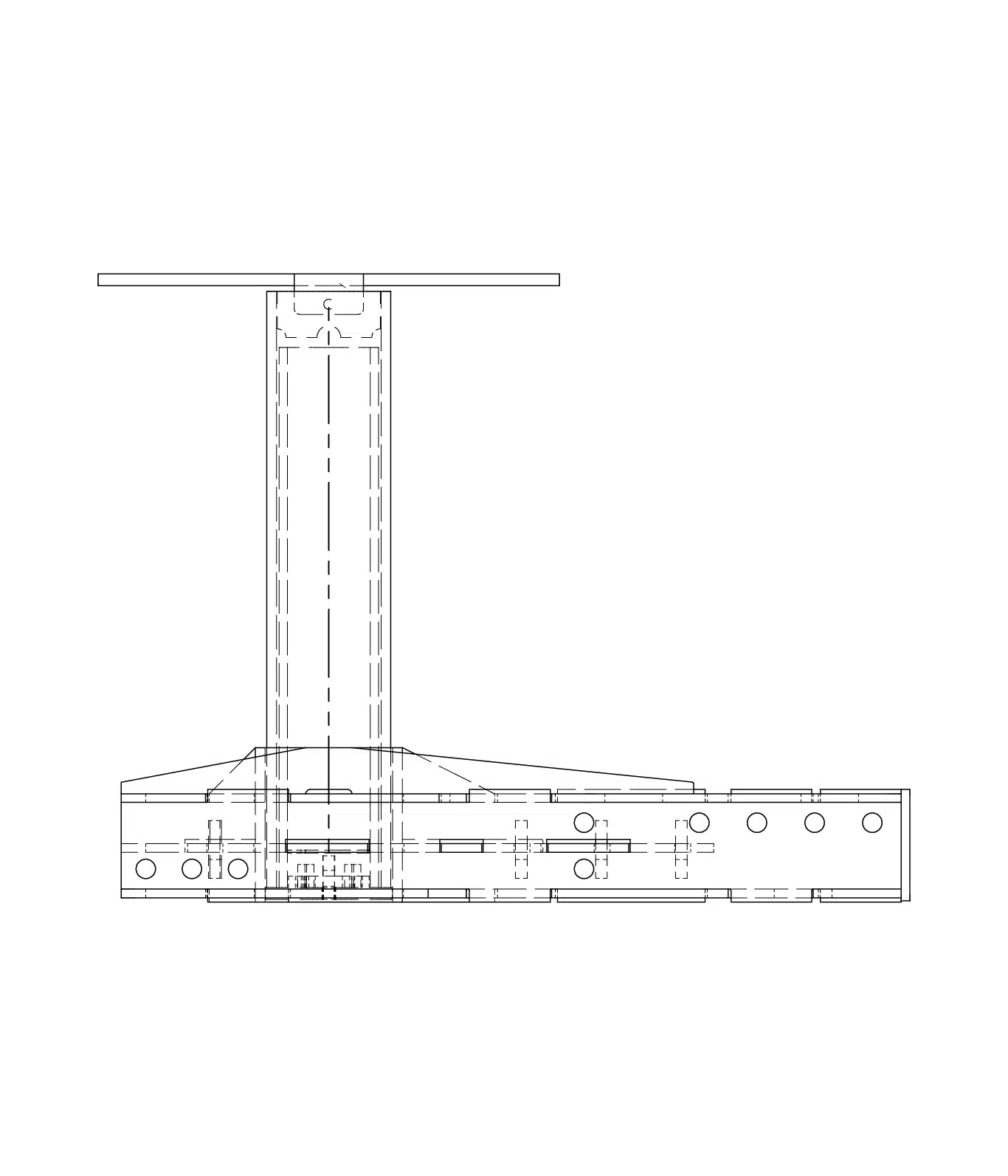

Patriot M50 Shallow Mount Removable Bollard – R-1009-12-SM-R

USD $5,289.00

The Patriot R-1009-12-SM-R combines shallow foundation engineering with removable functionality for unmatched versatility. Engineered to ASTM F2656 M50 P1 standards, it is capable of stopping a 15,000 lb vehicle at 50 mph with minimum penetration. This bollard allows for flexible access while delivering uncompromising perimeter defense. Proudly manufactured in America from high-strength steel, the Patriot R-1009-12-SM-R ensures both security and compliance with Buy America mandates.

Key Features:

- Engineered to meet the ASTM F2656 M50 P1 standard

- Shallow mount installation minimizes excavation depth

- Removable for adaptable access control

- 100% Made in America, Buy America compliant

- Ships ready for installation with primed black coating

Designed for sites requiring both flexibility and maximum crash resistance, the Patriot R-1009-12-SM-R is an essential solution for high-risk security zones.

| Qty | USD$ |

|---|---|

| 1 - 9 | 5,289 |

| 10 - 49 | 5,138 |

| 50 - 99 | 4,995 |

| 100 + | Call for pricing |

- Product Drawing (PDF)

- CSI Construction Specs (DOC)

- Installation Best Practices (PDF)

- Product Warranty (PDF)

If you require more resource materials, please contact our customer service department.

| Weight (lbs) |

2235 |

|---|---|

| Function |

Removable Crash Engineered Bollard |

| Height (in) |

39 1/2 |

| Body Diameter (in) |

10 3/4 |

| Material |

Steel |

SECTION 11 12 43

VEHICLE BARRIER SYSTEMS

GENERAL

- SUMMARY

- Section Includes:

- Crash-rated bollards.

- [_________________]

- Related Requirements:

- [Section 03 30 00: Cast-in-Place Concrete]

- [Section 28 13 63 - Access Control Vehicle Identification System]

- [_________________]

- Section Includes:

- REFERENCE STANDARDS

- Department of Defense (DoD) approved and listed on Anti-Ram Vehicle Barrier List

- SUBMITTALS

- Manufacturer’s Product Data

- Comply with Section [01 33 00 – Submittal Procedures.] [_________.]

- Product Data: Provide for each type of bollard, component, finish, and accessory specified.

- Maintenance Data: Submit manufacturer’s field touch-up, cleaning, and maintenance instructions.

- Warranty Documentation: Submit sample of manufacturer’s warranty.

- Setting Drawings: Show embedded items and cutouts required for work specified by other Sections.

- Manufacturer’s Product Data

- QUALITY ASSURANCE

- Comply with Section [01 43 00 – Quality Assurance.] [_________.]

- DELIVERY, STORAGE, AND HANDLING

- Comply with Section [01 66 00 – Product Storage and Handling Requirements.] [_________.]

- Protect bollards and accessories during delivery, storage, and handling.

- WARRANTY

- Comply with Section [01 78 36 – Warranties.] [_________.]

PRODUCTS

- MANUFACTURERS

- Manufacturer: Reliance Foundry Co. Ltd.

- Phone: 604-547-0460 or 1-877-789-3245

- Fax: 604-590-8875

- Website: https://www.reliance-foundry.com/bollard

- Email: info@reliance-foundry.com

- Substitutions: [Comply with provisions of [Section 01 25 00 "Substitution Procedures"] [_________] for substitution procedures.] [Not allowed.]

- Manufacturer: Reliance Foundry Co. Ltd.

- CRASH-RATED BOLLARDS

- Crash-rated bollard [Designer’s Designation]:

- Model: Reliance Foundry; R-1009-12-SM-R.

- Height: 52 7/8 in (134.3 cm)

- Height Above Grade: 39-1/2 in (100.3 cm)

- Diameter: 10 3/4 in (27.3 cm)

- Weight: 2235 lbs (1013.8 kg)

- Design: Removable Shallow Mount M50 Crash Engineered Bollard

- Material: Steel.

- Country of Origin: United States

- Finish: Paint coated.

- Color Coating:

- Type: Paint.

- Color: [Black]

- Installation:

- Concrete Embedded

- Crash-rated bollard [Designer’s Designation]:

EXECUTION

- EXAMINATION

- Examine paving or other substrates for compliance with manufacturer’s requirements for placement and location of embedded items, condition of substrate, and other conditions affecting installation of bollards.

- Proceed with installation only after unsatisfactory conditions have been corrected.

- INSTALLATION

- General: Comply with manufacturer’s installation instructions and setting drawings.

- Do not install damaged, cracked, chipped, deformed, or marred bollards. Field touch-up minor imperfections in accordance with manufacturer’s instructions. Replace bollards that cannot be field repaired.

- CLEANING & PROTECTION

Normal cleaning may be done with clean water and a soft cloth. Detailed cleaning and inspection instructions are available at www.reliance-foundry.com/bollard/maintenance-bollards.

- Protect bollards against damage.

- Immediately prior to Substantial Completion, clean bollards in accordance with manufacturer’s instructions to remove dust, dirt, adhesives, and other foreign materials.

- Touch up damaged finishes according to manufacturer’s instructions.

- CLOSEOUT ACTIVITIES

- Provide executed warranty.

END OF SECTION

Durable Design

We create long-lasting infrastructure that reduces waste over time, by utilizing materials that are durable, recyclable, and that can be repurposed.

Conscious Manufacturing

We prioritize partnerships with manufacturers that share our values - those who use recycled materials and implement sustainable practices.

Giving Back To Nature

Buy A Bollard, Plant A Tree.

The heart of our sustainability initiative lies in giving back: we plant a tree for every bollard sold.

Reviews

There are no reviews yet.