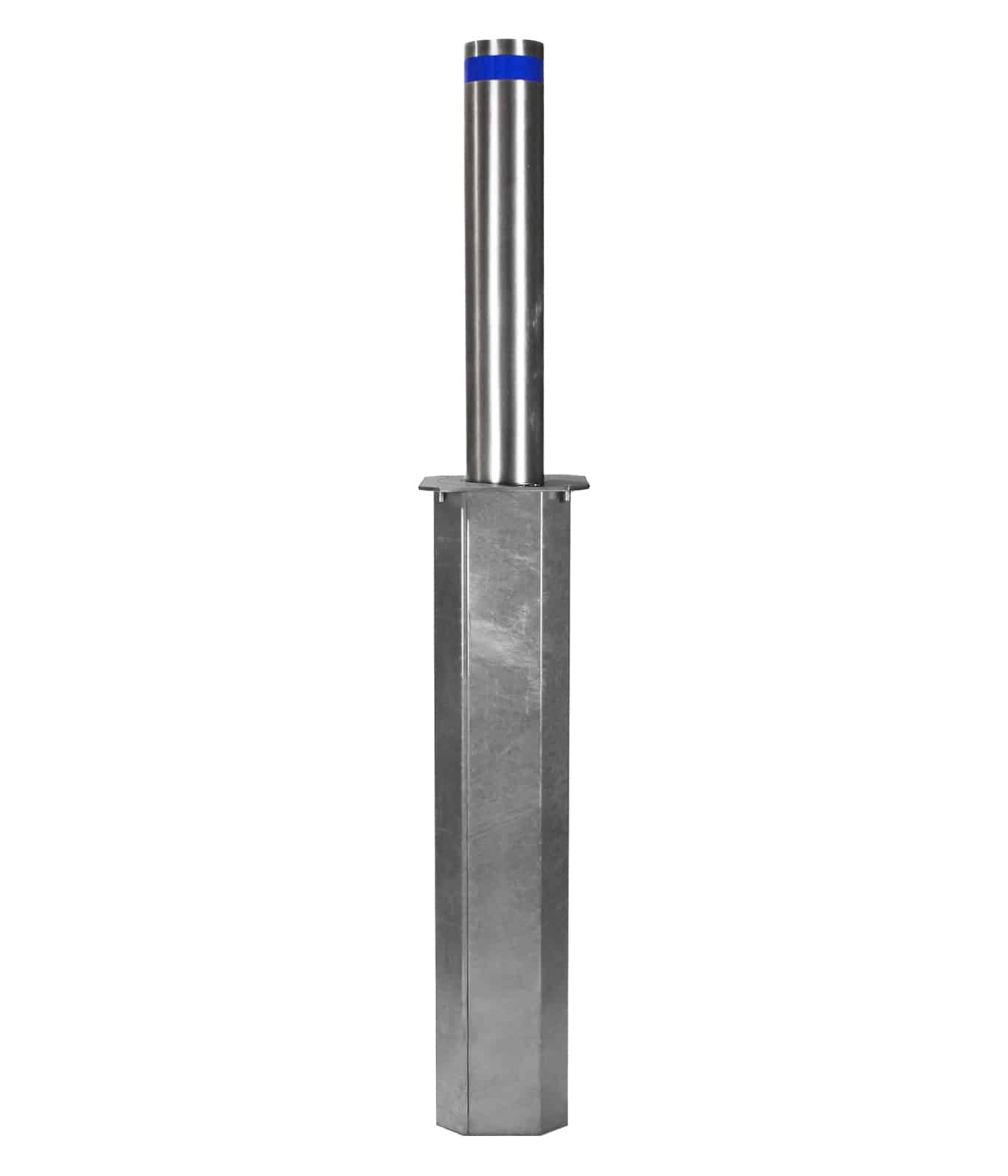

Zero Gravity Semi-Automatic Bollard – R-9001

USD $2,453.00

The R-9001 Zero Gravity Bollard is a semi-automatic retractable bollard engineered for smooth, intuitive operation with minimal physical effort. Designed for durability and long-term performance, it features a unique mechanical-assisted lift system—eliminating the need for hydraulics, gas struts, or external power sources.

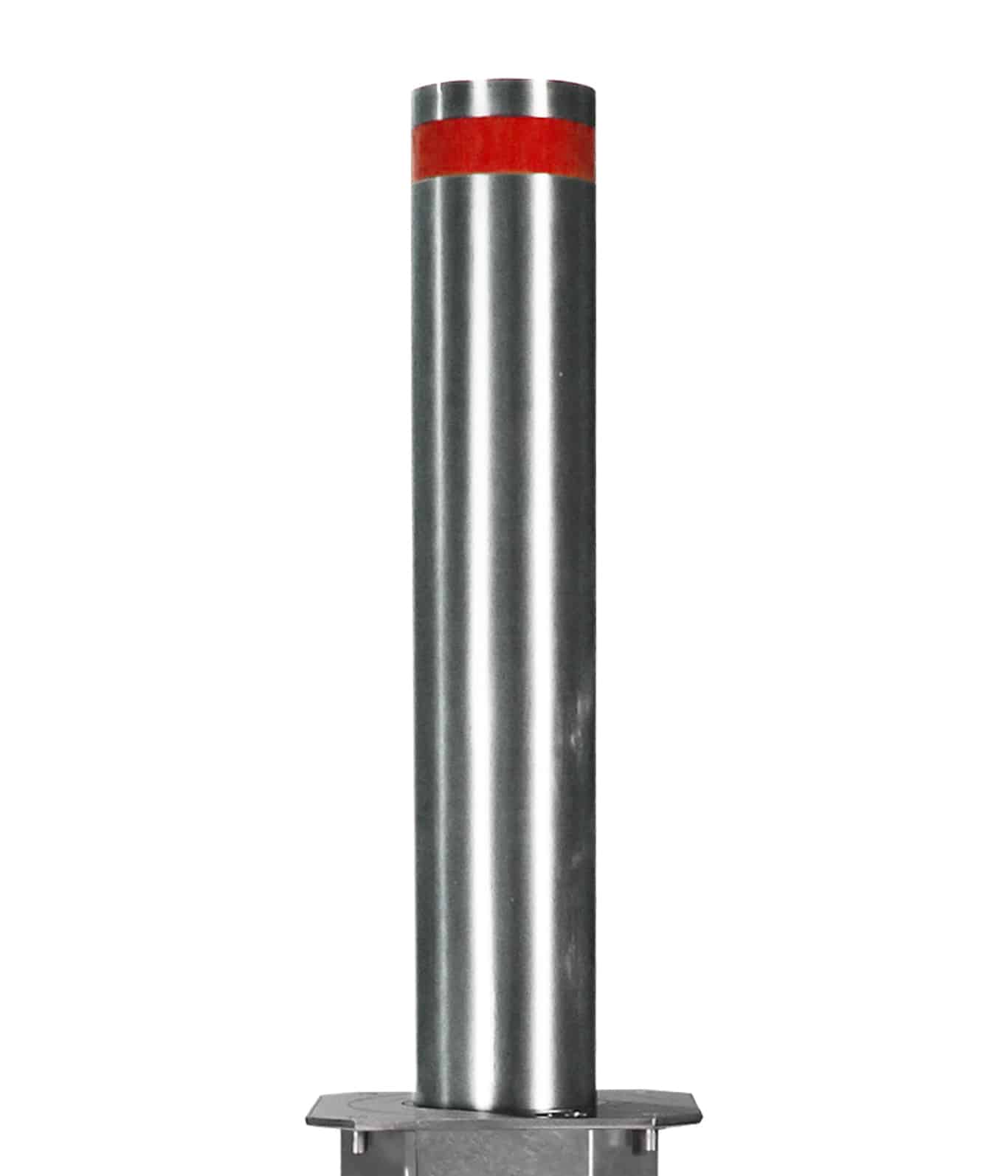

When unlocked, mechanical system reduces the load making it easy to fully extend with a light pull. It locks securely in both the raised and lowered positions and sits flush with the ground when retracted, maintaining an unobtrusive profile. Highly visible reflective tape is included to enhance safety and visibility in both day and night conditions.

Constructed from corrosion-resistant stainless steel, the R-9001 is built to withstand the elements and high-frequency use. All components are field-replaceable, providing a low-maintenance solution for secure access control in public and private spaces. The Zero Gravity bollard has also been tested to withstand temperatures from -40 °C to +50 °C.

Key Features:

- Mechanical-assisted lift system for effortless operation

- Easily raises or lowers with minimal physical effort

- No hydraulics, gas struts, or power source require

- Corrosion-resistant stainless steel construction

- Locks in both raised and lowered positions

- Field-replaceable components for easy maintenance

- Tested for a minimum of 2,700 up/down cycles

| Qty | USD$ |

|---|---|

| 1 | 2,453 |

| 2 | 2,397 |

| 3 | 2,373 |

| 4 | 2,346 |

| 5 - 9 | 2,322 |

| 10 - 24 | 2,298 |

| 25 - 49 | 2,275 |

| 50 - 99 | 2,255 |

| 100 | 2,232 |

| 101 + | Call for pricing |

Loading...

- Product Drawing (PDF)

- AutoCAD Drawing (DWG zipped)

- Sketchup (SKP)

- CSI Construction Specs (DOC)

- Installation Best Practices

- Service Manual (PDF)

- Product Warranty (PDF)

If you require more resource materials, please contact our customer service department.

| Lockable |

Double Locking |

|---|---|

| Weight (lbs) |

204 |

| Function |

Retractable |

| Height (in) |

36 |

| Body Diameter (in) |

6 5/8 |

| Material |

Stainless Steel |

| Duty Cycles |

5 per day for 18 months |

SECTION [32 39 13.15]

METAL ACCESS CONTROL BOLLARDS

GENERAL

- SUMMARY

- Section Includes:

- Removable bollards

- Retractable bollard set

- Collapsible bollards

- Accessories

- [_________________]

- Related Requirements:

- [Division 03 Sections: [Concrete] [Mortar] fill for security posts.]

- Section Includes:

- REFERENCE STANDARDS

- ASTM A36 – Standard Specification for Carbon Structural Steel.

- ASTM A312 – Standard Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipes.

- ASTM A500 – Standard Specification for Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and Shapes.

- ASTM A536 – Standard Specification for Ductile Iron Castings.

- ASTM B26 – Standard Specification for Aluminum-Alloy Sand Castings.

- SUBMITTALS

- Comply with Section [01 33 00 – Submittal Procedures.] [_________.]

- Product Data: Provide for each type of bollard, component, finish, and accessory specified.

- Color Samples: [Submit manufacturer’s standard colors for selection.] [Submit sample of color specified.]

- Setting Drawings: Show embedded items and cutouts required for work specified in other Sections.

- Maintenance Data: Submit manufacturer’s field touch-up, cleaning, and maintenance instructions.

- Warranty Documentation: Submit sample of manufacturer’s warranty.

- QUALITY ASSURANCE

- Comply with Section [01 43 00 – Quality Assurance.] [_________.]

- DELIVERY, STORAGE, AND HANDLING

- Comply with Section [01 66 00 – Product Storage and Handling Requirements.] [_________.]

- Protect bollards and accessories during delivery, storage, and handling.

PRODUCTS

- MANUFACTURERS

- Manufacturer: Reliance Foundry Co. Ltd.

- Phone: 604-547-0460 or 1-877-789-3245

- Fax: 604-590-8875

- Website: https://www.reliance-foundry.com/bollard

- Email: info@reliance-foundry.com

- Substitutions: [Comply with provisions of [Section 01 25 00 "Substitution Procedures"] [_________] for substitution procedures.] [Not allowed.]

- Manufacturer: Reliance Foundry Co. Ltd.

- RETRACTABLE BOLLARD SET

- Material:

- Bollard: ASTM A240, 316 Stainless Steel.

- Top Plate: ASTM A240, 316 Stainless Steel.

- Base: ASTM A36 or equivalent, Carbon Steel

- Country of Origin: Malaysia

- Bollard [Designer’s Designation]:

- Model: Reliance Foundry; r-9001.

- Height Below Ground: 59 7/16 inches (150.9 cm)

- Height Above Ground: 36 inches (91.4 cm)

- Diameter: 6 5/8 in (16.8 cm)

- Weight: 204 lbs (93 kg)

- Design: Semi-Automatic Retractable Bollard with flat top..

- Lock: extended and lowered

- Duty Cycles: 5 per day for 18 months

- Finish: Satin No.6

- Installation:

- Retractable, New Concrete:

- Receiver

- Locking: In raised position.

- Footing: [3000 psi minimum concrete or mortar.] [[Concrete] [Mortar] as specified in Section [__ __ __].]

- Fill: [Aggregate.] [Aggregate as specified in Section [__ __ __].]

- Retractable, Existing Concrete:

- Receiver

- Locking: In raised position.

- Footing: [3000 psi minimum concrete or mortar.] [[Concrete] [Mortar] as specified in Section [__ __ __].]

- Fill: [Aggregate.] [Aggregate as specified in Section [__ __ __].]

-

- Material:

EXECUTION

- EXAMINATION

- Examine paving or other substrates for compliance with manufacturer’s requirements for placement and location of embedded items, condition of substrate, and other conditions affecting installation of bollards.

- Proceed with installation only after unsatisfactory conditions have been corrected.

- INSTALLATION

- General: Comply with manufacturer’s installation instructions and setting drawings.

- Do not install damaged, cracked, chipped, deformed or marred bollards. Field touch-up minor imperfections in accordance with manufacturer’s instructions. Replace bollards that cannot be field repaired.

- CLEANING & PROTECTION

- Protect bollards against damage.

- Immediately prior to Substantial Completion, clean bollards in accordance with manufacturer’s instructions to remove dust, dirt, adhesives, and other foreign materials.

- Touch up damaged finishes according to manufacturer’s instructions.

- CLOSEOUT ACTIVITIES

- Provide executed warranty.

END OF SECTION

Durable Design

We create long-lasting infrastructure that reduces waste over time, by utilizing materials that are durable, recyclable, and that can be repurposed.

Conscious Manufacturing

We prioritize partnerships with manufacturers that share our values - those who use recycled materials and implement sustainable practices.

Giving Back To Nature

Buy A Bollard, Plant A Tree.

The heart of our sustainability initiative lies in giving back: we plant a tree for every bollard sold.

Reviews

There are no reviews yet.